Safety Guidelines for Using the Ridgid 6 Gallon Air Compressor

Always unplug the compressor before servicing and drain the tank after each use to prevent rust․ Use a 10-12 gauge extension cord to avoid overload issues․

Ensure the pressure gauge and cut-out switch function properly to maintain safe operating levels․ Regularly inspect hoses and connections for leaks or damage to prevent accidents․

Never exceed the recommended pressure settings, and always follow the manufacturer’s guidelines for proper handling of compressed air to ensure safe operation and longevity of the unit․

1․1 Essential Safety Precautions Before Operation

Always unplug the Ridgid 6 Gallon Air Compressor before servicing or maintenance․ Inspect the unit and hoses for damage or leaks․ Wear safety goggles and ensure the area is well-ventilated․ Read the manual thoroughly to understand safety protocols and operational limits․

Check the tank and hoses for any leaks or damage before each use․ Ensure all connections are secure to prevent accidents during operation․

1․2 Proper Handling of Compressed Air

Always ensure the compressor is turned off before connecting or disconnecting hoses․ Check for leaks by applying soapy water to connections․ Use the correct pressure settings for your tools to avoid damage or injury․ Never direct compressed air at people or animals, as it can cause harm․

1․3 Emergency Shutdown Procedures

In case of an emergency, immediately turn off the compressor’s power switch and unplug it from the power source․ Release all compressed air from the tank by opening the drain valve․ Inspect for any issues before restarting, and consult the manual for specific guidance on handling emergencies safely and effectively․

Understanding the Ridgid 6 Gallon Air Compressor Components

The Ridgid 6 Gallon Air Compressor features a robust motor, durable pump, and a 6-gallon tank for storing compressed air․ It includes a pressure gauge, cut-out switch, and air filter for optimal performance․ Dual hose connections allow for multiple tool usage, enhancing versatility and efficiency in various applications․

2․1 Overview of Key Parts and Functions

The Ridgid 6 Gallon Air Compressor comprises essential components like the motor, pump, and 6-gallon tank for air storage․ The pressure gauge monitors air pressure, while the cut-out switch ensures safe operation by shutting off at maximum pressure․ The air filter cleans incoming air, and dual hose connections enable simultaneous tool usage, enhancing productivity and versatility in various tasks․

2․2 Importance of the Pressure Gauge and Cut-Out Switch

The pressure gauge monitors air pressure, ensuring it stays within safe limits․ The cut-out switch automatically shuts off the compressor at maximum pressure, preventing over-pressurization and potential damage․ Both components are crucial for safe operation and longevity of the unit, protecting against hazards and maintaining optimal performance during use․

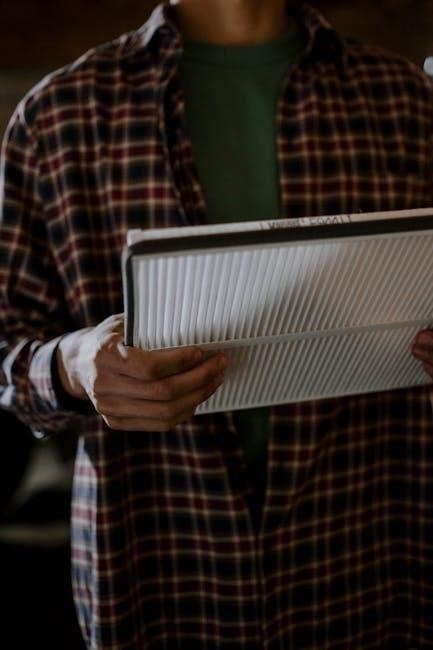

2․3 Role of the Air Filter and Tank

The air filter ensures clean air intake, preventing dust and debris from entering the compressor․ The tank stores compressed air, enabling consistent tool operation․ Regular drainage of the tank is essential to prevent rust and maintain performance, ensuring reliable operation and longevity of the Ridgid 6 Gallon Air Compressor․

Installation and Setup Instructions

Unpack and inspect all components, ensuring no damage․ Use a 10-12 gauge extension cord for power; Place the compressor on a level surface and ensure good ventilation for safe operation․

3․1 Unpacking and Initial Inspection

Remove all items from the carton and verify each part against the carton contents list․ Check for any damage or missing components․ Contact RIDGID customer service immediately if discrepancies are found․ Ensure the compressor and accessories are in good condition before proceeding with setup․

3․2 Connecting the Air Compressor to Power

Use a 10-12 gauge extension cord to connect the compressor to a suitable power source․ Ensure the outlet matches the compressor’s power requirements․ Avoid using damaged cords to prevent overload issues․ Always plug the compressor into a grounded outlet to maintain safety and proper operation․ Consult the manual for specific electrical requirements․

3․3 Setting Up the Tank and Hose Connections

Ensure the tank is securely connected to the compressor unit․ Attach hoses to the dual universal quick connectors, checking for leaks․ Tighten all fittings properly to maintain airtight seals․ Use Teflon tape on threaded connections for added security․ Regularly inspect hoses for damage to ensure safe and efficient operation․

Operating the Ridgid 6 Gallon Air Compressor

Start the compressor, monitor pressure, and adjust settings as needed․ Ensure efficient operation by using dual hoses and quick recovery feature․ Ideal for inflating tires and powering tools reliably․

4․1 Starting the Compressor for the First Time

Unpack and inspect the compressor, ensuring all parts are intact․ Plug in the unit, turn it on, and allow it to build pressure․ Monitor the pressure gauge and listen for smooth operation․ Check for any leaks in the tank or connections before first use․

For the Ridgid 6 Gallon, ensure the air filter is preassembled and the power head is ready․ After initial startup, let it run for a few minutes to test functionality․ Refer to the manual for specific startup procedures and settings to ensure optimal performance and safety․

4․2 Adjusting the Pressure Settings for Different Tasks

To adjust the pressure settings on the Ridgid 6 Gallon Air Compressor, locate the regulator knob near the pressure gauge․ Turn the knob clockwise to increase pressure and counterclockwise to decrease it․ Always refer to the manual for specific guidelines to ensure safe operation and optimal performance for various tasks like inflating tires or powering nail guns․

4․3 Using Dual Hose Connections for Multiple Tools

The Ridgid 6 Gallon Air Compressor features dual universal quick connectors, allowing simultaneous use of multiple air tools․ This enhances productivity on job sites by enabling two users to operate tools independently․ Ensure both hoses are securely attached to prevent air leaks and maintain consistent pressure for optimal performance across connected devices․

Maintenance and Care Tips

Regularly drain the tank to prevent rust and corrosion․ Clean or replace the air filter to ensure optimal airflow and performance․ Lubricate moving parts as recommended to maintain efficiency and extend the compressor’s lifespan․

5․1 Regular Drainage of the Tank to Prevent Rust

Drain the tank daily after use to remove moisture, preventing rust and corrosion․ This ensures the compressor operates efficiently and maintains its durability over time․ Always unplug before draining for safety․

5․2 Cleaning the Air Filter for Optimal Performance

Clean the air filter regularly to ensure optimal airflow and compressor efficiency․ Use compressed air or a soft brush to remove dust and debris․ Replace the filter if damaged or clogged to maintain peak performance and extend the unit’s lifespan․

5․3 Lubricating Moving Parts as Recommended

Lubricate moving parts with light machine oil as recommended to ensure smooth operation․ Apply oil after each use or as needed to prevent friction and wear․ Avoid over-lubrication, as it may attract dust and dirt, potentially damaging the compressor․ Regular lubrication helps maintain efficiency and extends the unit’s lifespan․

Troubleshooting Common Issues

Common issues include low air pressure, overload switch tripping, and leaks․ Check for proper power supply and drain the tank regularly to prevent rust and maintain performance․

6․1 Diagnosing Low Air Pressure Problems

Low air pressure issues can stem from leaks in hoses or connections, faulty pressure gauges, or improper settings․ Inspect all components for damage or wear, ensure tight connections, and verify the pressure switch calibration to resolve the issue effectively․

6․2 Resolving Overload Switch Tripping Issues

Overload switch tripping often occurs due to excessive current draw; Ensure a 10-12 gauge extension cord is used and avoid overloading the compressor․ Check for proper ventilation and verify the pressure settings․ Reset the switch only after addressing the root cause to prevent recurrent tripping and potential damage to the motor․

6․3 Fixing Leaks in the Hose or Connections

Inspect hoses and connections for visible cracks or wear․ Tighten loose fittings and replace damaged O-rings or gaskets․ Apply thread sealant like Teflon tape to threaded connections․ Regularly check for air leaks by applying soapy water; bubbles indicate leaks․ Ensure all connections are secure to maintain optimal air pressure and efficiency․

Accessories and Compatible Tools

The Ridgid 6 Gallon Air Compressor is compatible with a variety of accessories, including high-quality air hoses, universal quick connectors, and pneumatic tools like nail guns and impact wrenches․ Dual hose connections allow for simultaneous tool operation, enhancing productivity and versatility in woodworking, automotive, and inflation tasks․ Use genuine Ridgid parts for optimal performance․

7․1 Recommended Air Hoses and Fittings

Use high-quality, flexible air hoses with a minimum 1/4″ diameter to ensure optimal airflow․ Compatible fittings include quick-connect couplers and adapters for secure connections․ Choose hoses rated for 150 PSI to handle the compressor’s maximum pressure․ Regularly inspect for leaks or damage to maintain efficiency and safety․ Genuine Ridgid parts are recommended for optimal performance․

7․2 Compatible Nail Guns and Pneumatic Tools

The Ridgid 6 Gallon Air Compressor is compatible with a variety of pneumatic tools, including nail guns, impact wrenches, and staple guns․ For optimal performance, use Ridgid-branded or compatible tools designed for 150 PSI․ Dual hose connections allow multiple tools to operate simultaneously, enhancing productivity in woodworking and automotive tasks․

7․3 Additional Attachments for Versatility

The Ridgid 6 Gallon Air Compressor supports various attachments like tire inflation kits, blow guns, and quick couplers․ These enhance functionality for tasks such as inflating tires or cleaning surfaces․ Optional carrying bags and accessory kits are available to organize tools, maximizing portability and convenience for garage, workshop, or job site use․

User Reviews and Feedback

Users praise the Ridgid 6 Gallon Air Compressor for its reliability, quick recovery time, and portability․ It excels in inflating tires and powering nail guns efficiently, making it a versatile tool for various tasks․

8․1 Customer Satisfaction with Performance

Customers highly rate the Ridgid 6 Gallon Air Compressor for its consistent performance in inflating tires and powering tools․ Its quick recovery time and dual hose connections enhance productivity, making it a reliable choice for both home and professional use․

8;2 Common Praises and Criticisms

Users praise the Ridgid 6 Gallon Air Compressor for its portability, quick recovery time, and dual hose connections․ Critics note occasional noise issues and the need for a higher-gauge extension cord, which can affect performance in some cases․

8․3 Real-World Applications and Use Cases

The Ridgid 6 Gallon Air Compressor excels in inflating tires, powering nail guns for woodworking, and supporting automotive tasks․ Its portability makes it ideal for garages, workshops, and job sites, while its dual hose connections enable simultaneous tool operation, enhancing efficiency in various projects and applications․

Technical Specifications of the Ridgid 6 Gallon Air Compressor

The Ridgid 6 Gallon Air Compressor features a 150 PSI capacity, robust electric motor, and lightweight design for portability․ Its dual hose connections and quick recovery time ensure efficient performance across various tasks, making it suitable for both home and professional use․

9․1 Capacity and Pressure Ratings

The Ridgid 6 Gallon Air Compressor offers a maximum pressure rating of 150 PSI, providing ample power for tools and inflation tasks․ Its 6-gallon tank capacity ensures sufficient air storage for prolonged use, making it ideal for both light-duty and medium-duty applications with consistent performance․

9․2 Power Requirements and Efficiency

The Ridgid 6 Gallon Air Compressor operates efficiently with a 120V power supply, drawing 20-30 amps depending on usage․ It features quick recovery times and dual hose connections, enhancing multitasking capabilities․ The unit is designed for energy efficiency, ensuring reliable performance while minimizing power consumption during operation․

9․3 Weight and Portability Features

The Ridgid 6 Gallon Air Compressor is designed with portability in mind, featuring a lightweight and compact design․ Its manageable weight allows for easy transportation, making it ideal for various work environments․ The unit includes a convenient handle for carrying, ensuring mobility without compromising performance․

Customer Support and Warranty Information

Contact Ridgid customer service at 1-800-4-RIDGID for assistance․ The warranty covers parts and labor for defects, with detailed terms outlined in the manual for easy reference․

10․1 Contacting Ridgid Customer Service

Reach Ridgid support at 1-800-4-RIDGID (1-800-474-3443) in the US and Canada, or 01-800-701-9811 in Mexico․ For inquiries, email info@ridgid․com․ Visit their website for online resources, troubleshooting guides, and warranty details to address any concerns or questions about your 6-gallon air compressor effectively․

10․2 Warranty Coverage and Terms

Ridgid offers a comprehensive warranty for the 6-gallon air compressor, covering defects in materials and workmanship․ The warranty period varies by component, with details outlined in the manual․ Register your product and retain the purchase receipt for warranty validation and seamless service coverage;

10․3 Online Resources for Manual and Troubleshooting

Download the Ridgid 6-gallon air compressor manual from the official website or authorized portals․ Troubleshooting guides and FAQs are available online to address common issues․ Visit Ridgid․com or contact customer support at 1-800-4-RIDGID for assistance with manual downloads and technical queries․

Popular Uses for the Ridgid 6 Gallon Air Compressor

The Ridgid 6-gallon air compressor is ideal for inflating tires, powering nail guns, and supporting automotive tasks․ Its portability and dual hose connections make it versatile for garage and woodworking projects․

11․1 Inflating Tires and Sports Equipment

The Ridgid 6-gallon air compressor efficiently inflates tires for cars, SUVs, and trailers, thanks to its quick pressurization feature․ It also works well for inflating sports equipment like basketballs and bike tires, making it a versatile tool for both automotive and recreational needs․

11․2 Powering Nail Guns for Woodworking

The Ridgid 6-gallon air compressor is ideal for powering nail guns, delivering consistent air pressure up to 150 PSI․ Its quick recovery time and dual hose connections allow seamless operation for trim and finish woodworking tasks, ensuring efficient performance for professionals and DIY enthusiasts alike․

11․3 Use in Automotive and Garage Applications

The Ridgid 6-gallon air compressor excels in automotive and garage settings, efficiently inflating tires and powering tools like impact wrenches․ Its portability and quick pressurization make it ideal for tasks ranging from tire maintenance to general garage repairs, ensuring reliable performance for both professionals and hobbyists․

Downloading and Navigating the Manual

Visit the official RIDGID website to download the OF60150HA manual․ Use the search function to find your model, then download the PDF for easy reference and troubleshooting guide access․

12․1 Finding the Correct Manual for Your Model

Visit the RIDGID website and use the search bar to enter your model number, such as OF60150HA, to locate the specific manual․ Ensure compatibility by verifying the model number matches your compressor for accurate information and safe operation․

12․3 Saving and Printing the Manual for Future Reference

12․2 Navigating the Manual for Specific Information

Use the table of contents or index to quickly locate sections like troubleshooting or maintenance․ Search for keywords such as “pressure settings” or “tank drainage” to find relevant details․ The manual is organized to help users efficiently access information for optimal compressor performance and safety․